ELISA

Elevate your food safety testing with ELISA technology – ensuring reliable mycotoxin and allergen detection with quality and compliance.

Navigating Food Safety Testing with ELISAs: A Comprehensive Overview

The ELISA is a popular method used in laboratories worldwide for detecting and quantifying biomolecules. In the context of food safety, ELISAs are pivotal for detecting potential mycotoxins and allergens, ensuring product safety, product integrity, and verifying label claims.

What is an ELISA?

ELISA stands for Enzyme-Linked Immunosorbent Assay. It's a widely adopted laboratory method used for detecting and quantifying substances such as proteins, peptides, antibodies, and hormones. Think of an ELISA as a high-precision food detective that can sniff out even the tiniest traces of unwanted ingredients that might be hiding in a food product.

In the context of food safety testing, an ELISA functions similarly to a highly sensitive culinary critic, meticulously scrutinizing the food's composition. It involves coating a plate with antigens — anything that can trigger your immune system to produce antibodies — and then adding a sample of food product. If the food contains the target substance, such as a specific allergen or mycotoxin, it will bind to the antigen.

Next, a secondary antibody with an attached enzyme is added, which binds to any antigens that have latched onto the target substances from the food sample. A substrate is then introduced, which the enzyme converts to a detectable signal, often a color change. The intensity of this signal correlates directly to the quantity of the target substance captured from the food sample. This allows food safety professionals to quantify very precisely how much of a specific allergen is present in a given sample, ensuring products meet strict safety standards and are safe for consumption, especially by individuals with food allergies.

An ELISA's reliability and precision make it a cornerstone in the food industry's safety protocols, ensuring that every item on the consumer's table is what it claims to be, without hidden surprises.

Competitive ELISA explained

How is an ELISA Conducted for Food Safety Testing?

The ELISA process begins by preparing a microplate that is pre-coated with antibodies specific to the target allergen or substance you wish to detect in the food sample. For instance, to test for the presence of peanuts, the plate will have antibodies that only attach to peanut proteins, peptides and antigens.

A food sample is then prepared and added to the wells of the plate. If the target allergen is present, it will bind to the antibodies on the plate. After the sample has had time to react with the coated plate, the well is washed to remove any unbound substances.

Next, a secondary antibody is added, which attaches to the allergen, forming a sandwich: the plate's surface, the allergen, and the secondary antibody on top. This secondary antibody is linked to an enzyme; hence the term 'enzyme-linked'.

After another washing step, a substrate solution is added to the wells. The enzyme reacts with this substrate, causing a visible color change. The color's intensity is directly proportional to the amount of allergen in the sample. By comparing the sample's color intensity to a known standard curve, you can quantify the exact amount of the allergen present in the food.

This method is highly sensitive, allowing food safety technicians to detect minute quantities of allergens, ensuring the safety and integrity of the food supply.

Benefits of ELISA

- High Sensitivity and Specificity: ELISAs can detect very low concentrations of antigens or antibodies in complex food samples, thanks to the high specificity of the antibody-antigen interaction. This is crucial for identifying specific foodborne toxins, allergens, or contaminants that are present in very small amounts.

- Versatility and Flexibility: ELISAs can be adapted to detect a wide variety of targets, including proteins, peptides, antibodies, hormones, and even small molecules, with the appropriate choice of antibodies. This makes it highly versatile for different types of food safety assessments, from detecting allergens to monitoring for specific contaminants.

- Quantitative Analysis: ELISAs provide quantitative data on the concentration of the target analyte in the sample. This is important for assessing the level of contamination or allergens in food products, aiding in risk assessment and ensuring compliance with safety standards.

- Cost-Effective: Compared to many other advanced analytical techniques, an ELISA is relatively cost-effective, especially when testing a large number of samples. This makes it accessible for routine use in food safety testing.

- Ease of Use and Automation: The procedure for ELISAs is straightforward, and many steps can be automated, which reduces the potential for human error and increases throughput. This is beneficial for laboratories that need to process a high volume of samples efficiently.

- Minimal Sample Preparation: ELISAs often require less complex sample preparation compared to other analytical methods. This saves time and reduces the risk of sample degradation or contamination during preparation.

- Robust and Reliable: ELISA kits are designed to be robust and provide reproducible results, which is critical for ensuring consistent food safety testing outcomes across different batches and laboratories.

- Standardization: Many ELISA kits come with standardized reagents and protocols, which help in maintaining consistency in testing procedures and results, facilitating comparative analyses and regulatory compliance.

- Rapid Results: The turnaround time for ELISA tests is relatively short, which allows for timely decision-making in controlling food safety risks and managing potential outbreaks.

- Widely Accepted: ELISAs are well-established and widely accepted methods in the scientific community for detecting specific analytes. Its use in food safety testing is supported by numerous studies and regulatory bodies, adding to its credibility and reliability.

Why is an ELISA Important in Food Production?

ELISAs play a crucial role in food production by providing rapid and accurate detection of allergens and mycotoxins, ensuring the safety and quality of food products. Their high sensitivity and specificity make them an indispensable tool for complying with regulatory standards and preventing food safety incidents.

Verifying Ingredients

For products claiming to be allergen-free, ELISA provides a highly sensitive and specific means to verify these claims, ensuring they meet safety standards and protect consumers with food allergies.

Detecting Contaminants

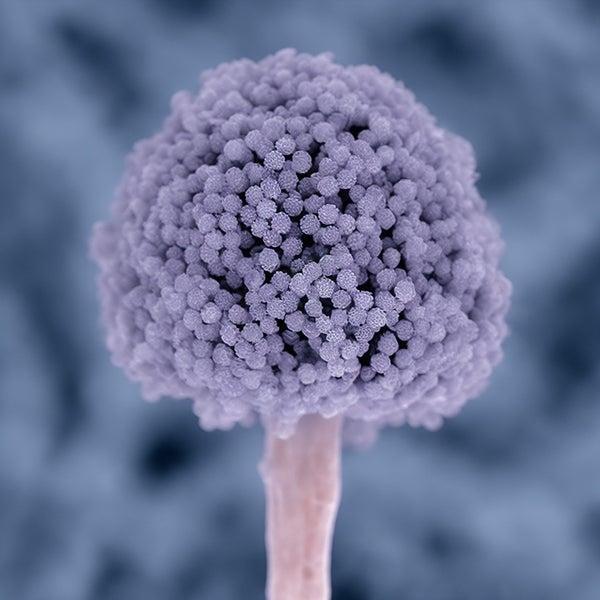

ELISA aids in swiftly detecting mycotoxin contaminants such as aflatoxins or ochratoxins in food products, ensuring that only safe food reaches the consumer.

Regulatory Compliance and Standards in ELISAs for Food Production

ELISA regulatory compliance for food safety testing is essential to ensure that food products adhere to established safety standards, safeguarding consumers from the hazards of contaminants and bolstering consumer trust in your brand. This compliance is akin to adhering to a meticulous recipe, ensuring the end product is not only enjoyable but also secure for consumption.

Key Regulations and Standards

- FDA Guidelines: In the United States, the Food and Drug Administration (FDA) prescribes guidelines for food safety testing that include the application of ELISAs, particularly for detecting allergens, mycotoxins, and pathogens.

- EU Regulations: The European Union enforces regulations for food safety that encompass the utilization of ELISA for identifying allergens, mycotoxins, and specific protein markers.

- ISO Standards: The International Organization for Standardization (ISO) offers standards such as ISO 22000 for food safety management systems, which recognize the importance of ELISA in hazard analysis within the food production chain.

Hygiena® is compliant to these standards. For more see our certifications.

Implementing Compliance in ELISA Testing

- Standard Operating Procedures (SOPs): Establish and adhere to SOPs for ELISA testing to guarantee consistent and dependable outcomes.

- Validation and Verification: Consistently validate and verify your ELISA methods to confirm their effectiveness and accuracy.

- Training: Ensure that your team is proficient in ELISA methodologies as well as the pertinent regulations and standards.

- Documentation: Maintain comprehensive documentation of all ELISA tests, including the methods, results, and compliance checks, to ensure accountability and traceability in your food safety practices.

You want to know more how to implement ELISA in your lab workflow?

Transform your lab's efficiency and accuracy: Contact us to explore our expert insights on integrating ELISA testing, and unlock the full potential of your lab workflow!

Key Takeaways for Food Production Professionals

In conclusion, ELISAs are not merely laboratory techniques; they're a foundational element in contemporary food production, pivotal for verifying the safety and integrity of food items. Their efficiency in identifying specific allergens, pathogens, and contaminants makes ELISAs an essential tool for safeguarding public health and bolstering consumer confidence.

- Highly Sensitive and Specific Detection: ELISAs are renowned for their exceptional sensitivity and specificity in detecting proteins and antigens, establishing them as a cornerstone in food safety testing.

- Versatile Applications in Food Safety: An ELISA's adaptability makes it invaluable across various aspects of the food industry, from screening for allergens and toxins to ensuring the purity and quality of ingredients.

- Improving Production Standards: The integration of ELISAs into food production processes can significantly enhance food safety and quality standards, contributing to more reliable and trustworthy food products.

Case Studies and Applications in Food Production

Dive into our selection of case studies and applications to see how ELISAs are being used in food production. These examples provide practical insights into how this technology is improving quality and efficiency in the industry.